Battery cabinet assembly automation system design

Welcome to our dedicated page for Battery cabinet assembly automation system design! Here, we have carefully selected a range of videos and relevant information about Battery cabinet assembly automation system design, tailored to meet your interests and needs. Our services include high-quality solar microgrid systems and battery energy storage solutions, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

Wherever you are, we're here to provide you with reliable content and services related to Battery cabinet assembly automation system design, including cutting-edge solar microgrid systems, advanced battery energy storage solutions, and tailored solar power storage applications for a variety of industries. Whether you're looking for large-scale utility solar projects, commercial microgrid systems, or off-grid power solutions, we have a solution for every need. Explore and discover what we have to offer!

Automated Battery Manufacturing Systems

Starting with the basics of your manufacturing process, Demco Automation™ creates custom automated assembly systems from the ground up using proven engineering approaches to

Product Information

Battery assembly solution

JOT Automation''s expertise in battery assembly automation allows us to deliver customized solutions tailored to your production needs. Our systems can handle the complexities of

Product Information

New Battery Test & Assembly System from McAlister Design & Automation

McAlister Design & Automation reveals its new Battery Test and Assembly System. This market-leading battery system enables the inspection and testing of battery cells

Product Information

New Battery Test & Assembly System from McAlister Design

McAlister Design & Automation reveals its new Battery Test and Assembly System. This market-leading battery system enables the inspection and testing of battery cells

Product Information

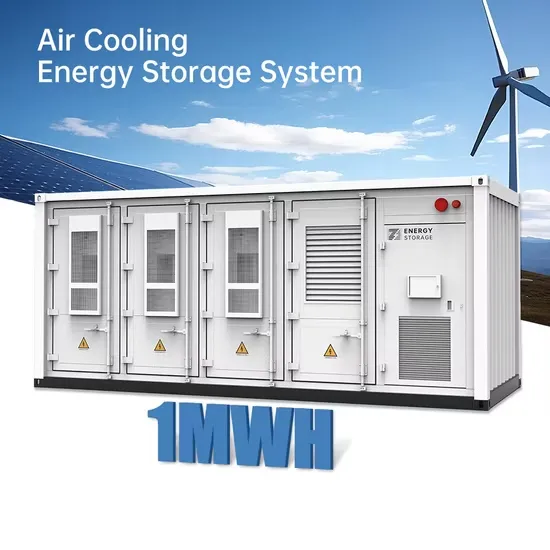

Utility-scale battery energy storage system (BESS)

BESS design IEC - 4.0 MWh system design — How should system designers lay out low-voltage power distribution and conversion for a battery energy storage system (BESS)? In this white

Product Information

New Battery Test & Assembly System from McAlister Design & Automation

Additionally, McAlister Design & Automation modeled the Battery Test & Assembly System around the 2170 battery for broader application benefits, including the many industries

Product Information

Advanced Lithium Battery Pack Automated Assembly Line System

This state-of-the-art production line achieves seamless automated battery pack production. Spanning an impressive 16 meters, it integrates cutting-edge technology through the following

Product Information

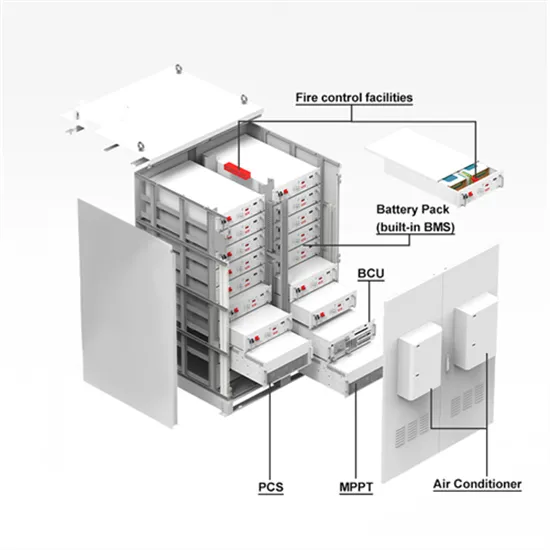

Energy storage cabinet assembly automation design

Leveraging our experience designing EV battery assembly lines, we are helping the energy industry design and scale battery manufacturing for grid energy storage.

Product Information

Advanced Lithium Battery Pack Automated Assembly

This state-of-the-art production line achieves seamless automated battery pack production. Spanning an impressive 16 meters, it integrates cutting-edge

Product Information

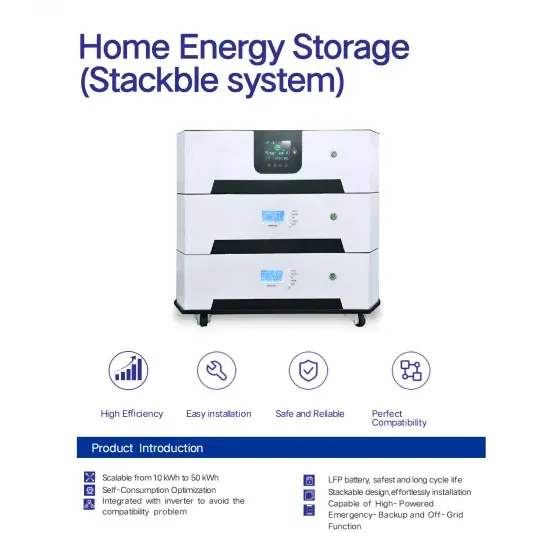

Battery Cabinets

The Battery cabinet is designed to house standard VRLA Batteries of capacity range from 24Ah to 105Ah (C10). The battery cabinets are available in 5 different mechanical dimensions, are able

Product Information

5 Automation Advantages for EV Battery Production

Battery assembly is a complex and highly technical process with little margin for error—the kind of process where automation shines. The increase in demand for electric

Product Information

Assembly line for battery modules and battery packs

For cell/module pack assembly, PIA Automation offers flexible and highly automated systems for the efficient production of battery cells, modules, and battery packs. These systems are

Product Information

Optimize Battery Assembly Line with Design and Automation

Discover the key features of a modern battery pack assembly line and how expert design and automation can boost performance, flexibility and output.

Product Information

Battery Cabinets | CrimEng

Energy Telecoms and Automation CompanyOur battery cabinet, also known as a battery enclosure or battery rack, is a specialized cabinet or housing designed to store and protect

Product Information

Battery Pack Assembly Line Smart Workstation Design

Modern battery pack assembly demands precision at every stage—from cell stacking to final testing. A smart workstation integrates hardware, software, and ergonomic

Product Information

Uninterruptible Power Supply (UPS) Backup Battery

Arimon offers several standard monobloc or top terminal battery cabinet sizes for 10 kVA to 125 kVA UPS systems accommodating monobloc batteries from 100

Product Information

Battery Energy Storage Manufacturing Automation | JR Automation

We can help you design and build systems to automate the production of battery energy storage systems (BESS) that will increase production and safety while reducing costs.

Product InformationFAQs 4

What is a battery assembly solution?

The comprehensive Battery Assembly solution can be equipped with an array of options, including unpacking, waste disposal, electrical testing, enclosure and casing assembly, PCB assembly, laser welding and final-product testing. Plus the solution's compartmentalized design ensures high-grade fire safety to keep its processes and surroundings safe.

Why is battery assembly important?

In the competitive world of electric vehicles and energy storage, efficient and precise battery assembly is crucial for meeting high performance and safety standards. At JOT Automation, we provide cutting-edge solutions for battery module assembly and battery pack assembly, ensuring seamless integration and optimized production.

What is the Jot battery assembly solution?

Watch the JOT Battery Assembly Solution in action. JOT Automation’s industry-leading battery assembly solution is a fully complete, turnkey solution for battery assembly that is also EV battery compatible. Highlights include automated unpacking of incoming material, testing, welding applications and final-product testing.

What are the technical parameters of intelligent battery pack?

Intelligent battery pack finished product handling and packaging system. 3: Technical Parameters: Total production line length: 16 meters. Production capacity: Up to X battery packs per hour (customizable). Precision level: ±0.1mm positioning accuracy. Processing efficiency: 99.5% uptime.

Related reading topics

- Best-selling photovoltaic panel custom manufacturer

- Canadian mobile communication base station

- Mauritania Communication Base Station Battery Energy Storage Cabinet

- Bhutan battery energy storage cabinet manufacturer

- Peruvian energy storage photovoltaic energy storage company

- Energy Storage Battery System Requirements

- Energy storage container 1MWH

- Japan Energy Storage Base Station Project

- Solar Off-Grid Photovoltaic Remote Site Energy Prices

- Product Introduction of Energy Storage Container Solar Photovoltaic Modules

- Polish energy storage container size design

- The vanadium battery energy storage system covers an area

- Photovoltaic panel household dimensions and specifications

- North Korea s new energy storage supporting requirements

- Zn-Nickel Flow Battery Safety

- Belarus box-type energy storage power station

- How many volts does a 660 watt photovoltaic panel have

- Mozambique communication base station inverter grid-connected cost price

- Three-phase inverter

- Integrated solar-storage energy storage solution

- Wind power generation photovoltaic communication base station inverter grid connection

- German Photovoltaic Energy Storage BESS Branch

- How Much Does Energy Storage Photovoltaic Invest in Turkey Cost

- How many mobile base station sites are there in the Netherlands

- 350W solar all-in-one machine

- Oman household energy storage cabinet manufacturer

- Photovoltaic module 125 cell