French pack battery processing

Welcome to our dedicated page for French pack battery processing! Here, we have carefully selected a range of videos and relevant information about French pack battery processing, tailored to meet your interests and needs. Our services include high-quality solar microgrid systems and battery energy storage solutions, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

Wherever you are, we're here to provide you with reliable content and services related to French pack battery processing, including cutting-edge solar microgrid systems, advanced battery energy storage solutions, and tailored solar power storage applications for a variety of industries. Whether you're looking for large-scale utility solar projects, commercial microgrid systems, or off-grid power solutions, we have a solution for every need. Explore and discover what we have to offer!

Li-Cycle to build French battery processing facility

(Reuters) - Li-Cycle Holdings Corp said on Monday it will build a French facility to break down batteries from forklift manufacturer The Kion Group, marking the latest expansion

Product Information

Battery recycling

A unique recycling technology Eramet Ideas, our Research & Innovation center, has developed a "closed-loop" recycling process. Unlike conventional processes, this process recycles metals

Product Information

Material & Processing Technology for Battery Pack

RAMPF presents high-performance resins, high-precision dispensing technology, and premium contract manufacturing services for sealing, casting, and

Product Information

Battery Cell Manufacturing Process

In order to engineer a battery pack it is important to understand the fundamental building blocks, including the battery cell manufacturing process. This will allow you to understand some of the

Product Information

Massive Battery Pack Processing In Factory

Ever wondered how the power bank in your pocket is built? 🔋 In this video, we take you inside the factory to see the entire process of making massive battery packs and power banks—from raw

Product Information

PRODUCTION PROCESS OF BATTERY MODULES AND

VDMA The VDMA represents more than 3,700 German and European mechanical and plant engineering companies. The Battery Production specialist department is the point of contact

Product Information

LG Energy Solution Establishes Battery Recycling Joint Venture

Under the agreement, LG Energy Solution will supply battery scrap from its facility in Poland, while Derichebourg will provide end-of-life EV batteries collected from France and

Product Information

Neogy® | French manufacturer of energy storage

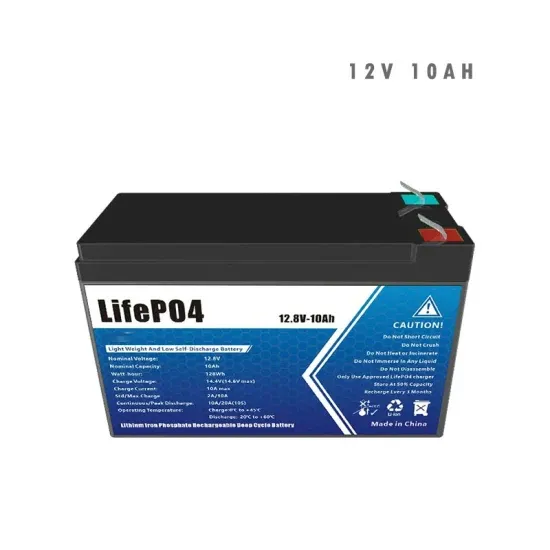

In terms of lithium battery technologies, two types dominate the industry: NMC (Nickel-Manganese-Cobalt) and LFP (Lithium-Fer-Phosphate) lithium-ion

Product Information

Production Process of Lithium Battery Pack Cells

The packaging of lithium-ion batteries is divided into two categories: metal shell batteries and pouch batteries. The production process of lithium battery pack cells is divided

Product Information

Neogy® | French manufacturer of energy storage systems

In terms of lithium battery technologies, two types dominate the industry: NMC (Nickel-Manganese-Cobalt) and LFP (Lithium-Fer-Phosphate) lithium-ion batteries. These two

Product Information

PRODUCTION PROCESS OF BATTERY MODULES AND

Attach or apply the seals (e.g. rubber seal, sprayed or bonded seals) to the edge of the housing or lid. Place the upper part of the housing or lid and connect it (e.g. by screwing) to the battery

Product Information

EV Battery-Pack Manufacturing Packs | DigiKey

This article reviews the complexities of EV battery packs and some related subassemblies, including the need for numerous battery cell modules, electrically efficient and

Product Information

9 Steps to Know How a Battery Pack Is Made

Manufacturing a high-quality battery pack is a complex process that requires precision, expertise, and strict quality control. From selecting the right materials to final inspection and testing, each

Product InformationFAQs 6

What is the battery pack manufacturing process?

The battery pack manufacturing process involves cell selection, module assembly, wiring, thermal management, and safety integration. Each step ensures efficiency, reliability, and durability. Understanding this process helps manufacturers optimize production, clients get tailored solutions, and consumers receive safer, longer-lasting batteries.

What are the final stages of the battery pack manufacturing process?

The final stages of the battery pack manufacturing process involve careful handling, transportation, and implementation to ensure products reach their destination safely and function as intended. Battery packs require specialized packaging to prevent damage: Each shipment contains essential information:

How do I engineer a battery pack?

In order to engineer a battery pack it is important to understand the fundamental building blocks, including the battery cell manufacturing process. This will allow you to understand some of the limitations of the cells and differences between batches of cells. Or at least understand where these may arise.

How to make a battery pack?

The journey towards crafting a battery pack begins with assembling individual battery cells. These cells, having undergone the transformation process to optimize their electrical performance, are now ready to be connected. Before this, it is essential to clean the surface of the cells thoroughly.

What is battery pack assembly?

The battery pack assembly is the process of assembling the positive electrode, negative electrode, and diaphragm into a complete battery. This involves placing the electrodes in a cell casing, adding the electrolyte, and sealing the cell.

How will emerging technologies transform battery pack manufacturing?

Emerging technologies will transform battery pack manufacturing: These developments collectively point toward battery packs with higher energy density, longer lifespan, faster manufacturing times, and substantially improved environmental credentials.

Related reading topics

- Solar Micro-Inverter System

- Photovoltaic panels for home storage

- Energy storage charging pile township

- Price of photovoltaic downgraded panels

- Total energy storage power stations in Asia

- Are photovoltaic solar panels insulated

- Mozambique energy-saving new energy photovoltaic energy storage

- New solar 30v photovoltaic panel

- 28000 high-frequency inverter

- What is the compressive strength of solar panels

- Export-oriented outdoor power supply

- EU export tariffs on photovoltaic modules

- Latest container-type lithium battery

- Photovoltaic panel power in 2025

- Malawian power storage system manufacturer

- French solar panel system subsidies

- How much does it cost to replace the new energy battery cabinet

- ASEAN Huijue Energy Storage Power Supplier

- Solar Energy Storage Container Company

- A solar panel factory in Iraq

- Explosion-proof photovoltaic solar panels

- Brazil Energy Storage Manufacturing Groundbreaking Project

- How big an inverter should I use for 1kW of solar power

- Africa Energy Storage Power Generation

- Battery paired with the inverter

- Two inverters with the same power

- Djibouti Photovoltaic Energy Storage Industry