What is the flow resistance of the battery cabinet liquid cooling system

Welcome to our dedicated page for What is the flow resistance of the battery cabinet liquid cooling system ! Here, we have carefully selected a range of videos and relevant information about What is the flow resistance of the battery cabinet liquid cooling system , tailored to meet your interests and needs. Our services include high-quality solar microgrid systems and battery energy storage solutions, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

Wherever you are, we're here to provide you with reliable content and services related to What is the flow resistance of the battery cabinet liquid cooling system , including cutting-edge solar microgrid systems, advanced battery energy storage solutions, and tailored solar power storage applications for a variety of industries. Whether you're looking for large-scale utility solar projects, commercial microgrid systems, or off-grid power solutions, we have a solution for every need. Explore and discover what we have to offer!

A review of battery thermal management systems using liquid cooling

Akbarzadeh et al. [117] explored the cooling performance of a thermal management system under different conditions: low current pure passive cooling, medium

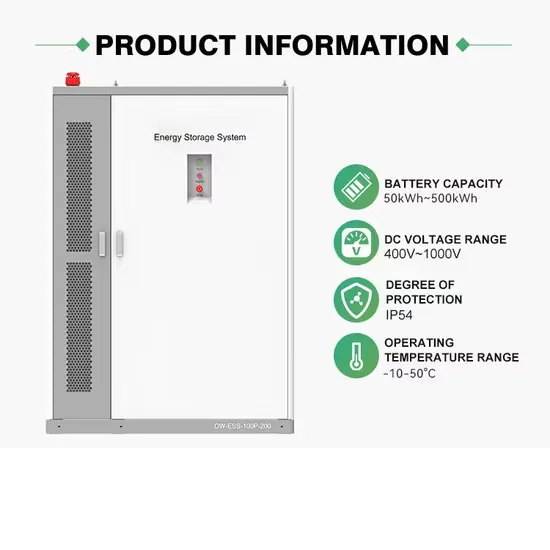

Product Information

Efficient Cooling System Design for 5MWh BESS Containers:

Operating battery cells above 35°C accelerates aging, resulting in faster degradation. The higher the temperature, the quicker the aging process, exacerbating battery

Product Information

Advances in flow pattern design of liquid-cooled components for

Research on liquid cooling channels is equally important, including optimization of the contact surface for reduced the thermal resistance, design of microchannel for enhanced

Product Information

Performance analysis of liquid cooling battery thermal

Abstract An efficient battery thermal management system can control the temperature of the battery module to improve overall performance. In this paper, different

Product Information

Liquid Cooling Battery Cabinet Technology Overview

By circulating a specialized coolant through channels integrated within or around the battery modules, it can absorb and dissipate heat much more efficiently than air. This method ensures

Product Information

Research and design for a storage liquid refrigerator

The liquid cooling temperature control system cools the battery through the uniform flow of the coolant in the liquid cooling plate at the bottom

Product Information

Battery Cells vs. Modules vs. Packs: How to Tell the Difference

What Is a Battery Pack? A battery pack integrates multiple modules and adds the systems that make the entire solution reliable: high-level BMS, power distribution, protection, and thermal

Product Information

Experimental and numerical investigations of liquid cooling plates

Additionally, based on the optimal flow pattern, the effect of the operating parameters of the liquid cooling system on the thermal performance of the battery is

Product Information

Battery Cooling Techniques in Electric Vehicle

Description: Liquid cooling circulates a coolant (often water-glycol mixtures) around or between battery cells to absorb heat and transfer it away from the battery.

Product Information

Channel structure design and optimization for immersion cooling

Compared with single-phase airflow, the airflow with a reciprocating period of 400 s can result in a reduction of 2.1 K in the maximum battery pack temperature and 4.5 K in

Product Information

Immersion cooling for lithium-ion batteries – A review

The aim of these systems is to remove heat from a battery pack, thus regulating the operating temperature, and to homogenise temperature within individual cells and between

Product Information

Liquid Cooling Systems: What is Used on Some Electric and

The liquid cooling system pumps a water-glycol mixture through precisely engineered cooling channels in direct contact with power electronics components. The coolant absorbs heat

Product Information

Analysis and design of module-level liquid cooling system for

An effective battery thermal management system (BTMS) can extend the service life of batteries and avoid thermal runaway. In this study, a liquid-cooling management system

Product Information

Channel structure design and optimization for immersion cooling system

Compared with single-phase airflow, the airflow with a reciprocating period of 400 s can result in a reduction of 2.1 K in the maximum battery pack temperature and 4.5 K in

Product Information

Performance Analysis of the Liquid Cooling System for Lithium

In this study, the effects of battery thermal management (BTM), pumping power, and heat transfer rate were compared and analyzed under different operating conditions and

Product Information

EV Battery Cooling System – How Does It Work?

EV battery cooling plate Car batteries can overheat during charging or high-speed driving. This raises safety concerns and performance risks. Proper temperature control

Product Information

Requirements and calculations for lithium battery liquid cooling

In this study, the effects of battery thermal management (BTM), pumping power, and heat transfer rate were compared and analyzed under

Product Information

Thermal Characterization of Battery Cold Plates

Several design parameters were varied including fluid channel height, the number of flow turns, fin pitch, and type of coolant to determine their impact on the thermal performance.

Product Information

Battery Cooling Tech Explained: Liquid vs Air Cooling Systems

Air-cooled systems use ambient air flow - fans or natural convection - to carry heat away from the cells. They are simple and low-cost, since no coolant, plumbing or pumps are

Product Information

Liquid Cooling Systems

Liquid cooling systems are self-contained units that recirculate a coolant to a predefined temperature set point. There are two types of liquid cooling solutions. The first is a liquid heat

Product Information

Advances in flow pattern design of liquid-cooled components for battery

Research on liquid cooling channels is equally important, including optimization of the contact surface for reduced the thermal resistance, design of microchannel for enhanced

Product Information

Requirements and calculations for lithium battery liquid cooling system

For liquid cooling systems, the basic requirements for power lithium battery packs are shown in the items listed below. In addition, this article is directed to the case of indirect

Product Information

What is liquid-cooled battery cooling? – TYCORUN

In the indirect contact liquid cooling system, the cooling liquid flows in the pipe and contacts the battery through a medium such as fins or heat sinks to take away heat, thereby

Product Information

Liquid Cooling: Efficiency in Battery Storage

High-density battery packs generate significant heat during operation, and without effective cooling, they face risks of reduced efficiency, premature degradation, and even safety

Product InformationFAQs 6

Why does a liquid cooling plate reduce the temperature of a battery?

The reason for this phenomenon was the temperature difference between the coolant and the battery pack. The liquid cooling plate can extract more heat from the battery pack, leading to a quicker reduction in temperature.

What factors influence the thermal efficiency of liquid-cooled battery pack systems?

Various factors influencing the thermal efficiency of liquid-cooled battery pack systems were systematically examined. The primary findings demonstrated that the innovative design of a battery pack cooled by variable-temperature coolant could significantly decrease the maximum temperature variation inside the battery pack.

Which coolant maintains the temperature uniformity of a battery?

Jithin and Rajesh performed a numerical analysis on the immersion cooling effect of three different coolants (deionized water, mineral oil and engineering fluid). The results show that all coolants maintained the battery's temperature uniformity.

How to maintain the average temperature of a battery module?

Based on this, a cooling plate with six channels was applied to both the top and bottom parts, and the top and bottom cooling showed sufficient cooling performance in maintaining the average temperature of the battery module below 45 °C. 1. Introduction

Does liquid-cooling plate connection affect thermal performance of battery pack?

The effects of liquid-cooling plate connections, coolant inlet temperature, and ambient temperature on thermal performance of battery pack are studied under different layouts of the liquid-cooling plate. Then, A new heat dissipation scheme, variable temperature cooling of the inlet coolant, is proposed.

How does liquid cooled battery cooling work?

Liquid-cooled battery cooling structures can be divided into passive and active. In the passive system, the liquid exchanges heat with the outside air to send the battery heat out; in the active system, the battery heat is sent out through liquid-liquid exchange. Table 1 Thermal conductivity of water at different temperatures

Related reading topics

- 600w double glass panel

- 220W home solar panel

- Flywheel Energy Storage Power Station System

- What is a communication base station inverter

- Wind power generation and energy storage for home use

- Latvian integrated photovoltaic module equipment is affordable

- Swaziland Photovoltaic Power Supply and Energy Storage System

- Huawei European Photovoltaic Energy Storage Power Supply

- Uruguay high-frequency inverter structure

- Andorra photovoltaic power station energy storage

- Heishan New Energy Storage Project

- Kenya lithium energy storage module price

- Operational model of frequency regulation of energy storage power stations

- Photovoltaic energy storage power generation design

- The role of the battery cabinet protection system

- Photovoltaic panels in South Sudan

- The future of lead-acid batteries

- Bulgaria Huijue Solar Inverter

- Main functions of Canada BMS battery management system

- Solar 48v power supply system

- Nepal communication base station wind and solar hybrid power generation quotation

- Venezuela small communication base station inverter grid connection

- Energy storage battery unit capacity

- How much energy storage equipment is needed for a 620 kW power station

- New Energy Storage BESS Policy

- Price of photovoltaic solar panels installed in Russia

- How many watts should a rural solar all-in-one machine choose