New energy battery cabinet bottom plate processing

Welcome to our dedicated page for New energy battery cabinet bottom plate processing! Here, we have carefully selected a range of videos and relevant information about New energy battery cabinet bottom plate processing, tailored to meet your interests and needs. Our services include high-quality solar microgrid systems and battery energy storage solutions, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

Wherever you are, we're here to provide you with reliable content and services related to New energy battery cabinet bottom plate processing, including cutting-edge solar microgrid systems, advanced battery energy storage solutions, and tailored solar power storage applications for a variety of industries. Whether you're looking for large-scale utility solar projects, commercial microgrid systems, or off-grid power solutions, we have a solution for every need. Explore and discover what we have to offer!

Battery Processing Systems | Quintus Technologies

Quintus has been at the forefront of this innovation, providing advanced isostatic pressing solutions to support solid-state battery production from the lab to full-scale manufacturing.

Product Information

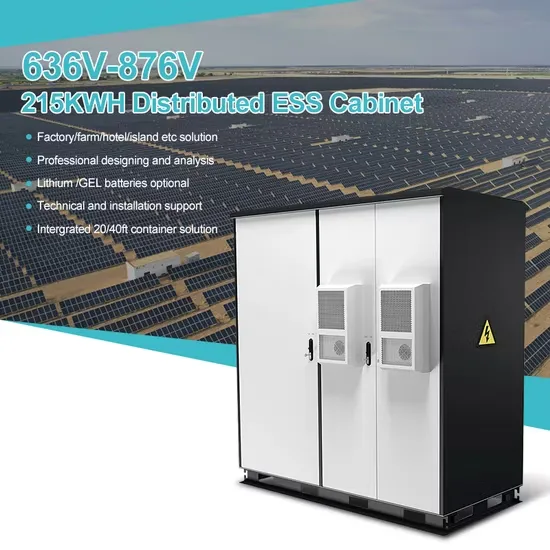

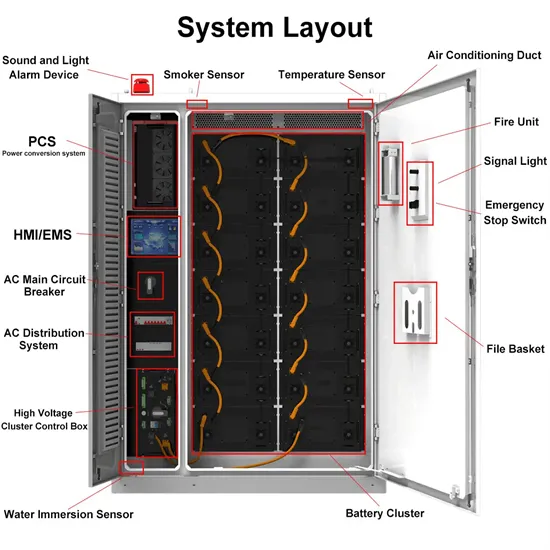

Quality Energy Storage Container & Energy Storage

China leading provider of Energy Storage Container and Energy Storage Cabinet, Shanghai Younatural New Energy Co., Ltd. is Energy Storage Cabinet factory.

Product Information

New Energy Battery Storage Box Customization: Tailored

This daily drama perfectly illustrates why new energy battery storage box customization isn''t just a luxury – it''s becoming the industry''s secret weapon. From solar farms to electric vehicle fleets,

Product Information

How AZE Systems Manufactures BESS Battery Energy Storage

With years of experience, cutting-edge technology, and a commitment to quality, AZE Systems delivers state-of-the-art BESS cabinets that meet the needs of diverse

Product Information

Battery Processing Systems | Quintus Technologies

Quintus has been at the forefront of this innovation, providing advanced isostatic pressing solutions to support solid-state battery production from the lab to full

Product Information

Battle for the EV Battery Box

Potential applications include battery-pack bottom plates where impact resistance is key. However, the new alloy requires special manufacturing processes the added cost of

Product Information

Liquid Cooling Battery Cabinet: Revolutionizing Energy Storage

The result is a system that runs more quietly, efficiently, and reliably, forming the backbone of truly resilient Liquid Cooled Battery Systems. Advantages of Next-Generation

Product Information

Battery cooling plate assembly and method for preparing the

The coolant passage may be formed at the same time by electromagnetic pulse welding, which may cancel the step of stamping, thus may decrease manufacturing cost of the battery cooling

Product Information

Energy Storage Liquid Cooling Plate Processing: Techniques,

As you dive deeper into energy storage liquid cooling plate processing, remember this: The difference between a good thermal solution and a great one often lies in the details –

Product Information

Battery swapping station for electric vehicles

Vehicle entrance & exit and safety detection Common problems and technical difficulties When the vehicle enters the battery swapping station, the bottom

Product Information

Forming Battery cabinet

The formation battery cabinet is the key equipment for battery manufacturing, and the precise control of the battery is realized through the precision manufacturing process. It plays an

Product Information

Production Process of Battery Modules and Battery

PDF | On Oct 25, 2023, Heiner Heimes and others published Production Process of Battery Modules and Battery Packs | Find, read and cite all the research

Product Information

Skid Plates: A Must-Have Accessory for New Energy

One way to protect your new energy car''s battery pack from these risks is to install a skid plate. A skid plate is a protective panel that is attached

Product Information

Safe transportation device for new energy battery piece processing

The safe transportation device for new energy battery piece processing can facilitate workers to pick up battery pieces one by one, and avoids the situation that the battery pieces fall off and

Product Information

Cooling Plate Manufacturing: Case Studies and Engineering Insights

Whether you''re a mechanical engineer, procurement manager, or involved in the high-voltage battery industry, this guide provides the insights needed to navigate the complexities of cooling

Product Information

Thermoplastic Underbody Skid Plates for Electric

MORE Advantages of CFRT as Underbody Skid Plates Thermoplastic underbody skid plates are designed to protect the bottom components of electric vehicles,

Product Information

Optimization design of battery bracket for new energy vehicles

As a consequence, it is particularly imperative to undertake lightweight design optimization for the battery bracket of new energy vehicles by applying 3D printing technology.

Product Information

Energy storage cabinet production and processing

What happened to energy storage systems? Industry attention was also devoted to the effectiveness of applications and the safety of energy storage systems, and lithium-ion battery

Product Information

What are the types of cold plates used in the new

The cold plate is a crucial part of the liquid cooling system. It effectively absorbs and transfers heat from the battery module or pack due to its excellent thermal

Product InformationFAQs 4

How does a cooling plate work?

The design and processing of these channels are crucial to the cooling plate’s performance. This method involves shaping the metal by pressing it into a die. Stamping is often used to create the initial form of the flow channels. It is a cost-effective process, suitable for high-volume production.

How are cooling plates made?

The first step in the manufacturing of cooling plates is material preparation. The choice of materials directly influences the performance, durability, and efficiency of the cooling plates. This process involves cutting raw materials, typically metals like aluminium or copper, into the desired size and shape.

How do you optimize a battery pack?

Optimizing the battery pack involves a host of manufacturing and material choices, mass and package tradeoffs, safety provisions, and structural design/engineering challenges, OEM and supplier experts told SAE Media.

What is a top cover for a battery box?

Top covers are typically a fire-retardant-loaded polymer or steel sheet, which resist internal fire for longer periods than aluminum and provide crash protection. But the Japan-based supplier is looking beyond just pack covers. “Our R&D group has developed SMC in five different formulations for battery boxes,” Foran said.

Related reading topics

- The largest company in grid-connected inverters for communication base stations

- Principle of container integrated solar cell

- Norway outdoor power supply assembly

- Are dual silicon inverters sinusoidal

- What equipment does the energy storage project include

- Solar Panel Outdoor On-site Energy Tracking

- Honduras special energy storage battery price

- Suitable for home use solar power generation system

- Ireland Eurasia Photovoltaic Power Generation 300w Photovoltaic Panel

- Benin Solar Cell Energy Storage

- Nordic energy storage station energy-saving equipment

- Lithuania Energy Photovoltaic Energy Storage

- Battery storage occupies land

- Sales cost of industrial and commercial energy storage projects

- Solar energy storage 20 kWh battery

- Barbados Energy Storage New Energy Company

- Wandudian lithium battery pack

- Libya outdoor portable power supply

- Niger photovoltaic integrated panel pressing tile manufacturer

- What is the actual power of photovoltaic panels

- Telluride thin film photovoltaic solar panels

- Ba Tie Outdoor Power Supply

- Burundi photovoltaic solar energy storage cabinet price

- 5g power grid base station security

- 330 Solar Photovoltaic Panels

- Energy storage cabinet battery module assembly site

- Which Swedish lithium energy storage power supply is better