Thickness of monocrystalline silicon photovoltaic panels

Welcome to our dedicated page for Thickness of monocrystalline silicon photovoltaic panels! Here, we have carefully selected a range of videos and relevant information about Thickness of monocrystalline silicon photovoltaic panels, tailored to meet your interests and needs. Our services include high-quality solar microgrid systems and battery energy storage solutions, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

Wherever you are, we're here to provide you with reliable content and services related to Thickness of monocrystalline silicon photovoltaic panels, including cutting-edge solar microgrid systems, advanced battery energy storage solutions, and tailored solar power storage applications for a variety of industries. Whether you're looking for large-scale utility solar projects, commercial microgrid systems, or off-grid power solutions, we have a solution for every need. Explore and discover what we have to offer!

Monocrystalline silicon photovoltaic panel specifications and

Choosing Between Monocrystalline and Polycrystalline Solar Panels. When investing in solar energy, a common question homeowners and businesses face is whether to choose

Product Information

Monocrystalline silicon

Monocrystalline silicon is also used for high-performance photovoltaic (PV) devices. Since there are less stringent demands on structural imperfections compared to microelectronics

Product Information

Fracture strength analysis of large-size and thin photovoltaic

With the development of technology, the size and thickness of monocrystalline silicon wafer are respectively getting larger and thinner, which cause an increase in silicon

Product Information

Monocrystalline silicon

OverviewIn solar cellsProductionIn electronicsComparison with other forms of siliconAppearance

Monocrystalline silicon is also used for high-performance photovoltaic (PV) devices. Since there are less stringent demands on structural imperfections compared to microelectronics applications, lower-quality solar-grade silicon (Sog-Si) is often used for solar cells. Despite this, the monocrystalline-silicon photovoltaic industry has benefitted greatly from the development of faster mo

Product Information

Structural diagram of monocrystalline silicon double

Download scientific diagram | Structural diagram of monocrystalline silicon double glass photovoltaic panel. EVA: ethylene-vinylacetate. from publication:

Product Information

Monocrystalline Silicon Cell

A monocrystalline silicon cell is defined as a photovoltaic cell constructed from single crystals, typically sliced from ingots, which achieves high efficiency through improvements in light

Product Information

Thickness of polycrystalline silicon photovoltaic panels

Monocrystalline silicon cells can absorb most photons within 20 mm of the incident surface. However, limitations in the ingot sawing process mean that the commercial wafer thickness is

Product Information

How thick is the solar monocrystalline silicon wafer? | NenPower

Monocrystalline silicon wafers, widely regarded for their efficiency, are crucial components in solar cells. The traditional thickness of these wafers has been around 180

Product Information

Thickness of polycrystalline silicon photovoltaic panels

The efficiencies of typical commercial crystalline silicon solar cells with standard cell structures are in the range of 16-18% for monocrystalline substrates and 15-17% for

Product Information

Solar panel types and differences: monocrystalline

The main types of solar panels on the market today are monocrystalline silicon, polycrystalline silicon and amorphous silicon solar cells. Differences between

Product Information

Monocrystalline silicon solar panel thickness standard table

Solar photovoltaic (PV) panels are a vital component of the global transition towards renewable energy sources and the development of PV technologies such as monocrystalline and

Product Information

Silicon Solar Cells: Trends, Manufacturing Challenges, and AI

Approximately 95% of the total market share of solar cells comes from crystalline silicon materials [1]. The reasons for silicon''s popularity within the PV market are that silicon is

Product Information

Monocrystalline

3.1.2 Polycrystalline cells Polycrystalline cell is a suitable material to reduce cost for developing PV module; however, its efficiency is low compared to monocrystalline cells and other

Product Information

Advancements in Photovoltaic Cell Materials: Silicon, Organic,

Mao''s research [16] explores the dominance and evolution of crystalline silicon solar cells in the photovoltaic market, focusing on the transition from polycrystalline to more cost-effective

Product Information

Free-standing ultrathin silicon wafers and solar cells through

Crystalline silicon solar cells with regular rigidity characteristics dominate the photovoltaic market, while lightweight and flexible thin crystalline silicon solar cells with

Product Information

Advantages & Disadvantages of Monocrystalline Silicon Solar Panels

1. Monocrystalline solar panels are the most expensive. From a financial standpoint, a solar panel that is made of polycrystalline silicon (and in some cases thin-film)

Product Information

Monocrystalline photovoltaic panels: what they are and their

Monocrystalline photovoltaic panels are advanced devices designed to convert sunlight into electrical energy through a process called the photovoltaic effect. Their

Product Information

How Thick Are Solar Panels? Solar Panel Size Explained

Most traditional solar panels measure between 30mm and 40mm (1.18 to 1.57 inches) thick. This thickness is typical for models that use crystalline silicon cells. New

Product InformationFAQs 6

What is a monocrystalline solar panel?

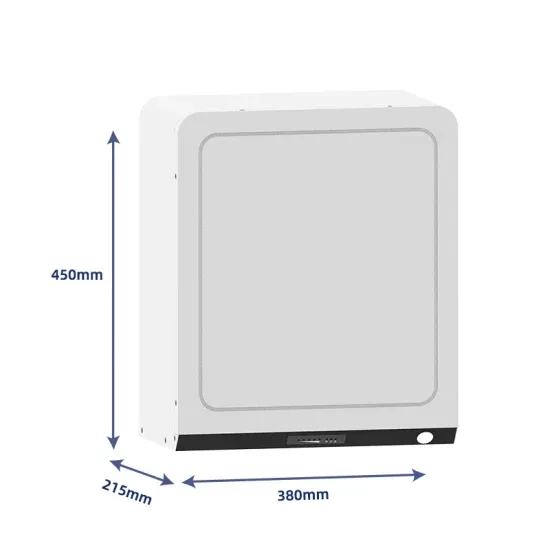

Monocrystalline Solar Panels are manufactured in 60, 72, and 96 cell configurations with a solar efficiency between 15-25%. Monocrystalline Solar Panels have typical heights of 64”, 76.5” (163, 194 cm), widths of 39”, 51.5” (99, 131 cm), and depths between 1.2”-2” (3-5 cm). Solar cell sizes are 6” x 6” (15 x 15 cm).

What is monocrystalline silicon based solar cell?

Monocrystalline silicon-based solar cells occupy a major share of the market with higher photoelectric conversion efficiency, and its market share is increasing year by year . Sawing monocrystalline silicon (mono-Si) brick into mono-Si wafers is the primary mechanical process to produce PV solar cell substrates.

How thick is a solar panel?

Solar cells are generally the thickest component of a solar panel, and their thickness can vary from about 200 micrometers (0.2mm) to 400 micrometers (0.4mm). The other main component of a solar panel is the glass cover, which has a typical thickness of 3mm. So, all in all, a small solar panel typically has a thickness of about 6.2mm.

Why is monocrystalline silicon used in solar panels?

Monocrystalline silicon is used to manufacture high-performance photovoltaic panels. The quality requirements for monocrystalline solar panels are not very demanding. In this type of boards the demands on structural imperfections are less high compared to microelectronics applications. For this reason, lower quality silicon is used.

How many m can a monocrystalline silicon cell absorb?

Monocrystalline silicon cells can absorb most photons within 20 μm of the incident surface. However, limitations in the ingot sawing process mean that the commercial wafer thickness is generally around 200 μm. This type of silicon has a recorded single cell laboratory efficiency of 26.7%.

What is monocrystalline silicon used for?

Monocrystalline silicon is also used for high-performance photovoltaic (PV) devices. Since there are less stringent demands on structural imperfections compared to microelectronics applications, lower-quality solar-grade silicon (Sog-Si) is often used for solar cells.

Related reading topics

- Maldives pack lithium battery equipment

- High-rise home solar water pump inverter

- Sri Lanka bidirectional portable energy storage emergency power supply

- Canadian Liquid Cooling Energy Storage Container Prices

- Are there subsidies for installing communication base station energy storage in the United States

- Rechargeable energy storage battery foreign trade

- How to connect the 48 power supply of the base station

- Tonga Energy Storage Power Station Gradient Battery

- South Africa distributed photovoltaic energy storage requirements

- How to install photovoltaic panels in container houses

- Sao Tome and Principe Quick PV Folding Container Wholesale

- Which inverter is better for 60v to 220v

- 50w solar water pump inverter

- Energy Storage Battery Brand Ranking

- 24 volt DC inverter

- Russian forest fire prevention communication base station wind and solar complementary

- Magnetic energy storage power generation

- Vietnam lithium energy storage power supplier

- Energy Storage Solar Storage and Charging Integrated System Topology

- Energy storage product price per watt

- Huawei Azerbaijan outdoor power supply brand

- Bhutan photovoltaic energy storage integrated device installation

- Photovoltaic panels installed on rural roofs in Malawi

- Cyprus lithium-ion energy storage battery system

- Philippines Energy Storage Power Station Project Price

- Iran Lithium Battery BMS Company

- The largest outdoor solar integrated machine